Industrial manipulators

Industrial Manipulators assist the operator in the work associated with moving, lifting, rotating and positioning of heavy loads. The industrial manipulators are useful tools to increase performance, safety and ergonomics. They also affect the improvement of productivity of the plant, the increase of quality of the products and the general competitiveness of the company.

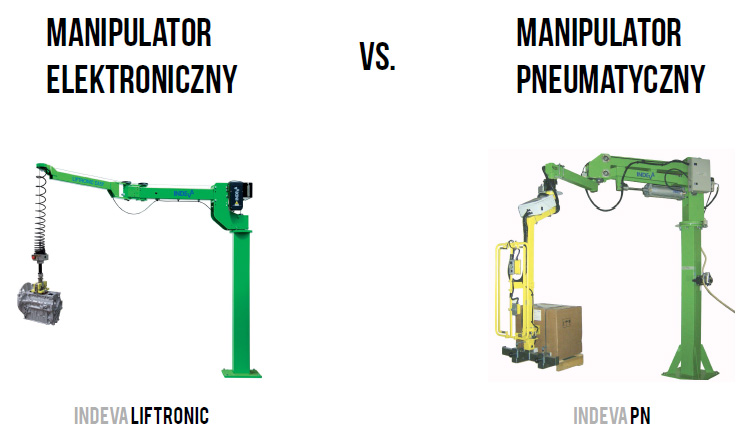

INDEVA, as one of the few manufacturers in the world, produces both traditional – pneumatic, as well as fully electronic, industrial manipulators with cable (oscillating system).

Pneumatic manipulators are reliable, robust and versatile, designed to carry loads with the centre of gravity offset beyond the axis.

Electronic manipulators (electronic balancers) have a more compact and lighter design, and they allow the operators to move loads faster and more accurate. They detect the weight of the object and are distinguished by a low inertia.

BRANCHES OF INDUSTRY

- Agriculture

- Automotive industry

- Automotive parts

- Bathroom and toilet accessories

- Ceramic Industry

Chemistry / Pharmacy - Electromechanical industry

- Electronics, computers and telecommunication

- Engineering

- Food / Beverage / Tobacco

- Foundry

- Furniture

- Glass and glass fibres

- Household appliances

- Mechanics

- Metal wires

- Motorcycles

- Paper production and printing

- Rubber / Plastics

- Textile industry

- Tyres

- Waste treatment

EFFICIENCY

Industrial manipulator contributes to productivity growth, it helps to reduce the risk of product damage and to minimize operator injuries associated with moving heavy loads.

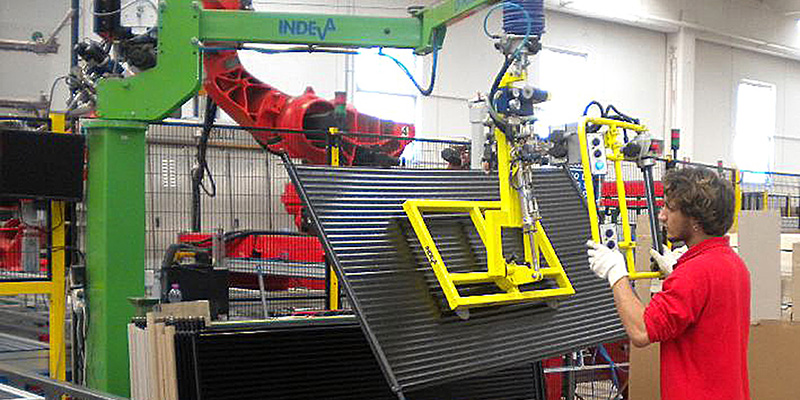

The INDEVA industrial manipulators are the most efficient handling equipment for manual handling of products, operating cycles that require rapid and repetitive movements. It is an ideal solution for performing rapid, repetitive movements and slow, precise positioning of loads. Thanks to the use of an industrial manipulator the operator can continuously perform the same operation within a few hours without fatigue.

Increasing efficiency and reducing the incidence and severity of employees’ injuries may lead to improvement of plant productivity, enhancement of product quality and overall competitiveness of the company.

SAFETY

Effective ergonomic interventions can reduce the physical requirements for the tasks within the handling of materials, reducing the incidence and severity of injuries of the musculoskeletal system that they may cause. Their potential for the reduction of costs associated with injuries makes the ergonomics a useful tool to improve plant productivity, to enhance product quality and overall competitiveness of the company.

ERGONOMICS

Thanks to the intelligent electronic control the INDEVA devices are faster, more responsive and more sensitive to the intentions of the operator. The hardware and software architecture with ergonomically designed grippers improves the operator comfort to the extent that the INDEVA industrial manipulators may truly be called an “extension of human hands.”

- auto sense of

load weight - no pneumatics

- for short working cycles

- precision

- low inertia

- light

- pneumatic system

- electronic control as an option

- stiff arm

- for working off the lifting axis

Only INDEVA among European manufacturers of industrial manipulators provides devices that belong to the family of Intelligent Assist Devices – IAD manipulators. Scaglia Indeva was the first company in the world to apply electronics to industrial manipulators. INDEVA has been a world leader in the manufacture of intelligent handling equipment since 1970.

In comparison with conventional manipulators the IAD devices offer the following advantages:

Precise positioning of the load as they allow for accurate and rapid movements, while traditional handling devices move too far, bounce and require lots of little corrective movements that, added to cycle time, reduce productivity.

Improved ergonomics requiring almost no effort from the operator. Thanks to the microprocessor based control, the system recognizes the operator’s intentions and supplies energy to overcome inertia both during acceleration and braking. The IADs respond to each, even a minimum, impulse of the operator much more quickly than the traditional pneumatic manipulators.

Speed: The IADs respond quickly, yet smoothly to human touch, overcoming the mass of inertia both during acceleration and braking, strengthening the operator’s movements. The operator does not notice the time lapse between detection of the operator’s intention by the device and its response. The IADs are not affected by the technological limitations of traditional pneumatic manipulators and hoists, thanks to modern digital drives and actuators. The intuitive control of the IAD systems compared to the conventional balancers, which are pre-set for one or two weights, lets them get automatically and immediately adjusted to the weight of the load, thus allowing to handle loads of varying weights without having the operator to reset the system each time. Moreover, thanks to digital technology, IADs can save the value of the load weight in order to allow direct handling (“float mode” or “hands on the load” control) with no need to use handles or to press buttons.

Handiness: Traditional handling devices require unwieldy and heavy lifting tools (grippers) while the IADs allow for light and compact lifting tools which provide better visibility during handling operations and greater ease of handling loads during moving and positioning.

DHC Systems zmienia się w DHC

Uprzejmie informujemy, że z dniem 1 lipca 2021 roku nastąpiło połączenie spółek DHC Sp. z o.o. ze spółką DHC Systems Sp. z o.o. Sp. k..

W wyniku połączenia spółka DHC Sp. z o.o. wstąpiła we wszystkie prawa i obowiązki spółki DHC Systems Sp. z o.o. Sp. k.. W związku z tym współpraca biznesowa oraz dostawy realizowane dotychczas przez DHC Systems Sp. z o.o. Sp. k będą realizowane w dalszym ciągu z najwyższą jakością i dbałością, jednakże podmiotem odpowiedzialnym za ich realizację będzie obecnie spółka DHC Sp. z o.o.

Poniżej nowe dane spółki:

DHC Sp. z o.o.

3 maja 22/1e

40-097 Katowice

NIP 634-24-87-764

KRS 0000049448

REGON 277648597